Raw Materials for Manufacturing Plants

Raw materials play a crucial role in the production process, and each manufacturing plant uses different materials based on its production needs. These materials can be natural, synthetic, or a combination of both, significantly impacting the quality, cost, and efficiency of the final products. Understanding the types of raw materials and their applications across various industries helps manufacturers optimize production processes and deliver high-quality products. This article provides a comprehensive review of raw materials for manufacturing plants, their types, applications, and role in the production process.

1. Types of Raw Materials for Manufacturing Plants

1. Types of Raw Materials for Manufacturing Plants

Raw materials used in manufacturing can be categorized into two main types:

1.1 Natural Raw Materials

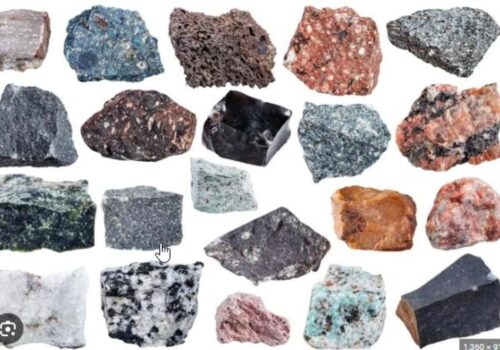

These materials are sourced from nature and typically include mineral, plant-based, and animal-based resources. Key examples include:

- Minerals: Limestone, silica, alumina, and sulfates are used in construction materials, cement, glass, and other mineral products.

- Plant-Based Materials: Wood, cotton, sugarcane, and wheat are utilized in industries such as textiles, food production, and paper manufacturing.

- Animal-Based Materials: Wool, leather, and hides are employed in the textile, footwear, and leather goods industries.

1.2 Synthetic Raw Materials

These are man-made materials, often derived from chemical processes, and include:

- Plastics: Polyethylene, polypropylene, and polystyrene are used for producing plastic products and packaging materials.

- Chemicals: Acids, bases, additives, and polymers are essential in the chemical and pharmaceutical industries.

- Metals: Iron, aluminum, and copper are critical for automotive, electronics, and industrial equipment manufacturing.

2. Applications of Raw Materials in Different Industries

The applications of raw materials vary across industries, depending on the type of product and technical requirements. Key applications include:

2.1 Construction Industry

- Raw Materials: Limestone, silica, clay, gypsum, and gravel.

- Applications: Used for manufacturing cement, bricks, plaster, tiles, ceramics, and concrete.

2.2 Food Industry

- Raw Materials: Wheat, rice, sugar, oil, and spices.

- Applications: Used for producing flour, edible oils, beverages, and packaged food products.

2.3 Textile Industry

- Raw Materials: Cotton, polyester, synthetic fibers, and wool.

- Applications: Used for manufacturing fabrics, clothing, and textiles.

2.4 Automotive Industry

- Raw Materials: Metals such as aluminum, plastics, rubbers, and cast iron.

- Applications: Used for manufacturing vehicle bodies, interiors, fuel systems, and electronic components.

2.5 Chemical Industry

- Raw Materials: Acids, bases, polymers, and additives.

- Applications: Used for producing detergents, pharmaceuticals, fertilizers, and petrochemical products.

3. The Role of Raw Materials in the Production Process

Raw materials are vital to the production process and influence several key aspects:

- Ensuring Quality: Using high-quality raw materials directly impacts the quality and durability of the final products.

- Cost Control: Selecting suitable raw materials can reduce production costs and increase profitability.

- Improving Efficiency: Optimizing raw material usage enhances production efficiency and minimizes waste.

- Environmental Sustainability: Using eco-friendly raw materials reduces the environmental impact of production.

4. Criteria for Selecting Raw Materials in Manufacturing Plants

When choosing raw materials, manufacturers must consider several criteria, including:

- Quality: Raw materials should meet required standards in terms of purity, chemical composition, and mechanical properties.

- Cost: Affordable raw materials contribute to overall profitability, and pricing should align with market demand.

- Availability: Materials must be readily accessible to ensure uninterrupted production.

- Compatibility: Materials must align with the production process to minimize operational challenges.

- Durability: Raw materials should provide adequate longevity to produce durable final products.

5. Production of Raw Materials in Manufacturing Plants

Raw materials are produced using advanced technologies and industrial processes. Production methods vary based on material type:

5.1 Production of Natural Raw Materials

These materials are extracted from natural sources and processed in specialized facilities. Examples include:

- Limestone for cement production.

- Gypsum for plaster manufacturing.

- Wood for producing timber and boards.

5.2 Production of Synthetic Raw Materials

These are manufactured through chemical and industrial processes in petrochemical plants, refineries, and specialized units. Examples include:

- Polymers and plastics.

- Processed metals.

Conclusion

Conclusion

Raw materials are fundamental to the production process and are applied differently across industries based on specific requirements. A thorough understanding of raw materials and their applications enables manufacturers to produce high-quality products while optimizing production processes. Selecting high-quality, cost-effective, and environmentally friendly raw materials can enhance production efficiency, reduce costs, and improve the quality of final products.